Controlled Modulus Columns (CMC) Offer Superior Foundation Solutions

Menard developed Controlled Modulus Columns CMC Soil Improvement in the 1990s to overcome problems of lateral confinement in highly compressible and organic soils. They are now used in all types of soil (cohesive or granular) up to depths of 30 metres or more.

Origin

Menard developed Controlled Modulus Columns in the 1990s to overcome problems of lateral confinement in highly compressible and organic soils. They are now used in all types of soil (cohesive or granular) up to depths of 30 meters or more.

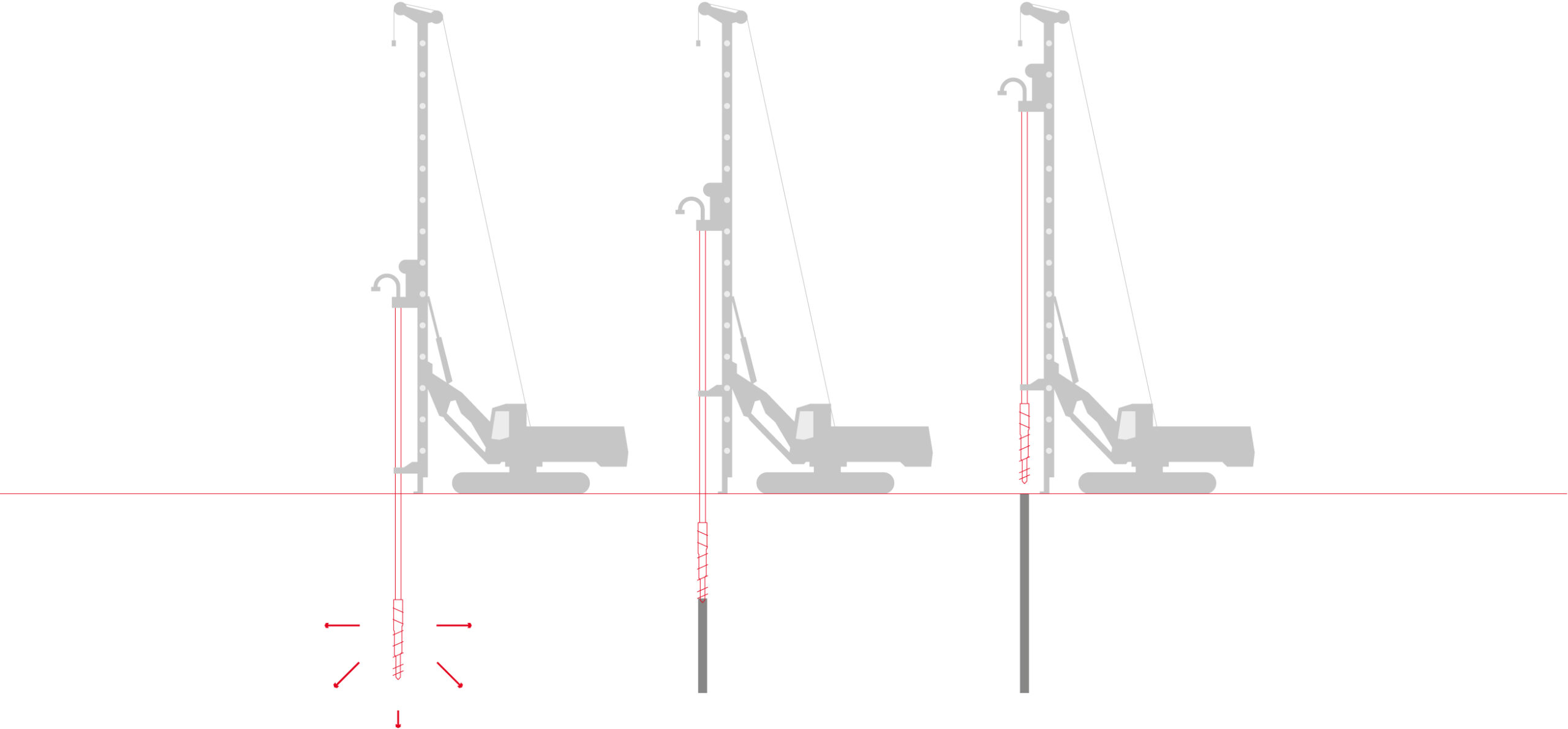

Implementation

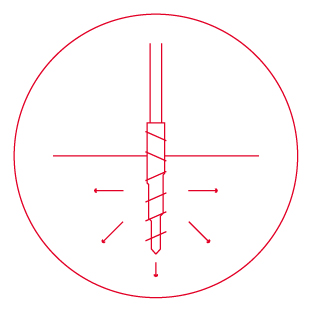

These inclusions are installed with or without soil displacement by low-pressure injection (generally up to 2 bars) of a grout or concrete through the hollow core of the drilling tool. These columns generally have a diameter of between 250 and 500 mm.

Advantages of Controlled Modulus Columns (CMC)

The main advantages of Controlled Modulus Columns CMC are rapid execution and significant reduction of settlement compared to untreated soil.

Controlled Modulus Columns (CMC) FAQ

Our company systematically controls cut-off to ensure the quality of the works. There is no risk of damage if earthworks are carried out according to best practices.

Groundwater is no obstacle. Care should be taken and the design should be adapted accordingly in cases where the water flow through the soil is high.