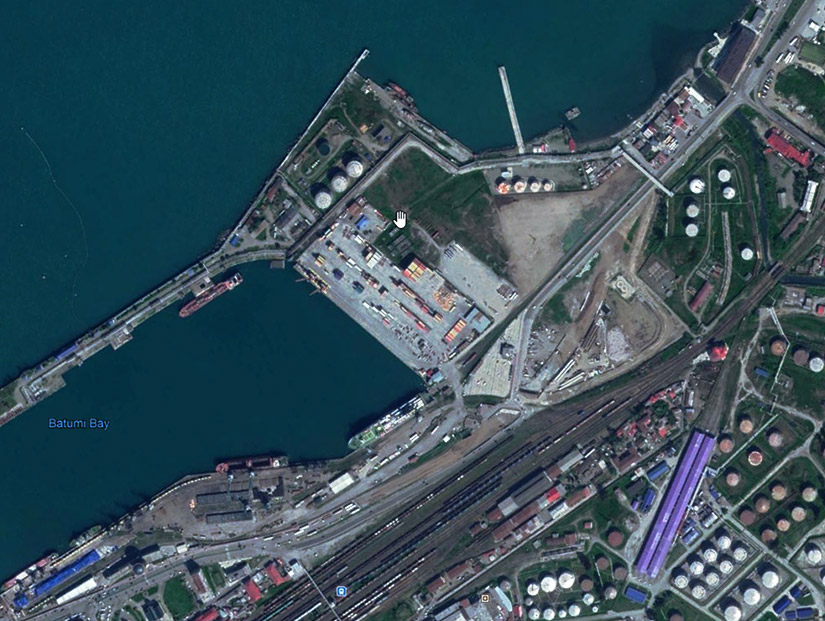

Menard Meca has successfully completed ground improvement projects in various sectors, including Buildings, Ports & Airports, Process & Energy, and Rail & Road. Our expertise in reinforcing building foundations on poor soil sites has resulted in stronger structures that can withstand even the most challenging environmental conditions. We have delivered projects in the Middle East (UAE, Kuwait, Egypt, Saudi Arabia, Oman, Qatar, and Bahrain), Turkey, and Kazakhstan.